Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Noticias

Noticias

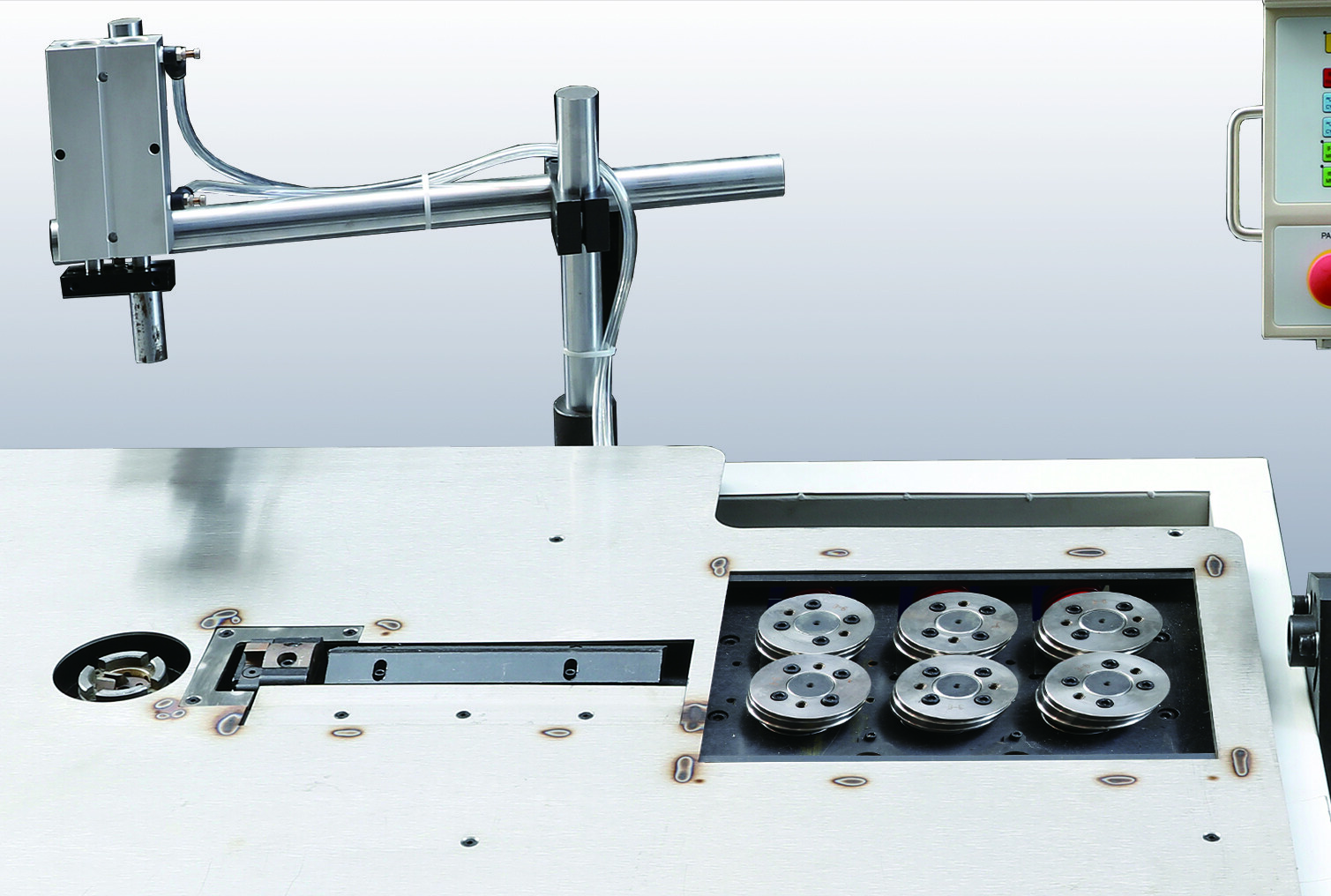

The Axis Motion Useage of Wire Straightening Machine

1. How to ensure the wire straightener machine of X and Y axis motion?

First of all, it should be clear that the wire straightener machine of an axis refers to its wire straightener machine in two planes. For example, the wire straightener machine of the pallet tool is carried on the guide rail, so the wire straightener machine of the guide rail determines the wire straightener machine of the motion. There are two reasons for the loss of the wire straightener machine. One is the wire straightener machine of the guide rail itself, and the other is the wire straightener machine of the guide rail installation reference surface. The combination of high-precision and stable guide rails, pallets, and lathe beds is the fundamental condition for ensuring a wire straightener machine. The high and low temperature and aging treatment of guide rails, pallets, and lathes also serve this purpose.

It is also obvious that the inconsistency of rollers (steel balls) will lead to fewer stress points or skidding.It should be noted that the irregular movement of the screw will also affect the guide rail. For example, the axial direction of the screw is not parallel to the guide rail, the center height of the screw and the screw mother is inconsistent, and the screw and the screw mother bear a torsional force and the screw The bending of the rod, etc., will interfere with the linear motion of the guide rail while the screw is moving. This is why we emphasize that the screw, screw nut, screw seat, and screw nut seat should be made accurately. Basic reasons for the norm.

Regardless of whether it is a "V" shape or an "I" shape, the guide rails and raceways must not be contaminated with any dirt or impurities. It will not only affect the wire straightener machine of the guide rail movement but also cause damage and deformation of the guide rails. The guide rails are required to be spotless. This is one of the rules for maintaining and maintaining machine tools to maintain long-term accuracy.

2. How to ensure the verticality of X and Y motion?

The verticality of the two axes is based on their respective wire straightener machine. The error of the straight line will be reflected in the verticality measurement. The result of numerical superposition will make the verticality measurement inaccurate and inaccurate. Therefore, the wire straightener machine of each axis must be ensured first. Then ensure mutual perpendicularity.

For the verticality of X and Y, the middle supporting plate is the key. The middle supporting plate has high precision and a stable structure, which is the basic condition for verticality. The verticality of the two axes completely depends on the verticality of the two sets of guide rails on the middle support plate. During assembly, one set of guide rails is fixed on the datum. After measurement and adjustment, the other set of guide rails is perpendicular to the datum, and then fixed and assembled. Drill pin holes to fix the verticality of the two sets of guide rails on the middle pallet. In this assembly and measurement process, the operation must be stable and effective, and the accuracy should also be intentionally improved. The control of this intermediate process index is very important because whether it is installation, repair, or effectiveness over some time, the accuracy will be reduced. If the allowable error value is fully used during the initial installation, the subsequent accuracy will be excessive and inaccurate. For example, if the accuracy standard of a certain machine tool is 0.02, the internal control accuracy during the first assembly should be below 0.012. The initial installation of important parts is strictly controlled and the pins and screws are reliable and effective. In addition, the guide rail itself is straight and precise, and the verticality of the two axes is guaranteed.

Like the wire straightener machine, the working condition of the screw is also an important factor affecting verticality. Any external force that forms a certain angle with the positioning surface of the guide rail will cause abnormal movement of the guide rail because the guide rail is only a guide rail and is not clamped. Therefore, once it is found that the verticality of the X and Y axes exceeds the standard, it is necessary to carefully determine whether it is caused by the deformation or dislocation of the guide rail itself or the movement of the screw. If it is caused by the guiding function of the guide rail, repeat the adaptation process of loosening and tightening the screw and nut at several positions, and the direction and value of the excess should be generally stable. If it is caused by the interference of the movement of the screw and nut, the direction and numerical regularity will be lost. Never blindly loosen the fixation of the guide rail or remove the pin. Any operation without judgment is useless. Once the guide rail's fixing loosening pin has been removed, the entire process of first installation and adjustment described above must be repeated.

Any measurement and adjustment must be carried out after the guide rail movement is stable. If there is a sudden jump and irregular twisting, it means that the guide rail is too dirty or has foreign matter. It must be resolutely wiped clean and lubricated before adjustment. This must be kept in mind.

If you are interested in our wire straightening machine, please contact us